Laboratory gravity separation testing is a critical step in mining and beneficiation, allowing scientists and engineers to determine the efficiency of various methods of separating valuable minerals from gangue material. The process involves using specialized laboratory equipment to exploit differences in specific gravity between particles. We will explore four common types of laboratory equipment used for gravity separation testing: jigs, spiral separators, shaking tables, and centrifugal concentrators. Understanding the capabilities and applications of these instruments enhances the understanding of mineral processing and helps make informed decisions for efficient separation technologies and commissioning large production lines.

Lab Jig Separator

Jig separators are another commonly used laboratory equipment for gravity separation testing. The device works by pulsating water through a bed of particles, causing them to stratify according to their respective densities. Heavier particles settle to the bottom, while lighter particles rise to the top, where they can be easily separated and analyzed.

Jig separators are usually compact in design and can be used for various purposes such as sample classification, separation, screening, impurity removal, particle size analysis, etc. It provides accurate results with minimal sample loss, making it suitable for small-scale experiments or analysis of various minerals.

Lab Centrifugal Concentrator

Centrifugal concentrator is a widely used equipment in gravity separation tests. It utilizes the principle of separating particles through high-speed rotation based on their density and size. Heavier ore particles are pushed to the outside of the centrifuge, while lighter impurities move closer to the center of the device. This type of equipment is often used to extract metal particles from ores.

Its miniaturization and portability make it easy to conduct rapid testing and evaluation of ore samples in the laboratory, and it can also quickly process large quantities of samples. In addition, centrifugal concentrators are versatile and can be customized to the specific requirements of separation testing by adjusting rotation speed, feed rate and other parameters as needed.

Lab Shaking Table

Shaking tables have a flat surface that vibrates horizontally, allowing particles to move along the shaking table according to weight and size. Designed to simulate the gravity concentration process, the tabletop has ripples along its length that create slight vibrations and cause the particles to move longitudinally. Heavier particles are deposited near the shallows, while the current carries lighter particles away. The device can adjust different vibration levels, allowing precise separation process control.

The Shaking table is versatile in processing various types of ores and minerals; whether it is gold, tin, tungsten, zircon, or any other precious metal or heavy mineral, the equipment can efficiently separate them based on their density differences.

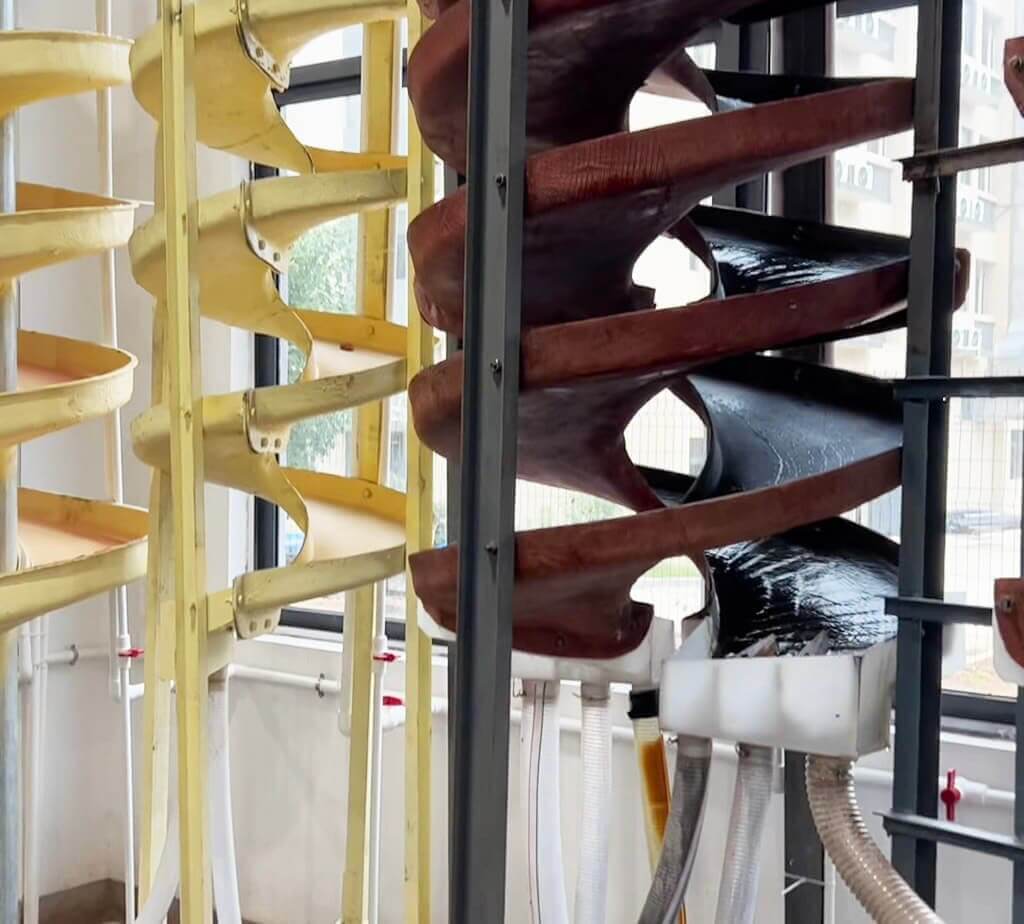

Lab Spiral Chute

This cylindrical device (a small helix with a vertical axis) relies on gravity and centrifugal force to separate solid particles based on their density differences. It employs a rotary motion that pushes denser materials toward the outer periphery while lighter materials move toward the center, producing efficient separation results.

The main advantage of the spiral chute is its ability to handle feed materials of various sizes. The device can efficiently separate particles up to 2 mm in size from fine sand to coarse ore. In addition, it has excellent recovery rates, ensuring that valuable minerals are not lost during the separation process.

Laboratory gravity separation is usually performed on a small scale and under controlled conditions for studies to determine optimal process flow and ore properties. The laboratory gravity separation equipment is available in various sizes and capacities, with a wide range of functionality. Our common lab gravity separation equipment includes shaking tables, spiral separators, centrifugal concentrators and jigs with a level of control that ensures reliable and consistent results; making it an indispensable tool for scientific research in mining, metallurgy and environmental analysis. Contact Asia Africa International to customize small or industrial mining equipment according to the specific requirements of the experiment and sample characteristics.