Laboratory mineral flotation experiments play a vital role in the mining industry as they provide important insights into ore quality and processing efficiency. By systematically studying the behavior of minerals in flotation cells, scientists and engineers can optimize the extraction process to achieve maximum recovery while minimizing environmental impact.

Additionally, laboratory flotation testing can serve as a valuable tool in evaluating different ores or evaluating potential sources for future mining projects. By simulating real conditions in a controlled environment, these experiments allow researchers to determine not only optimal operating parameters, but also potential challenges that may arise during large-scale production. However, when operating a flotation test, specific precautions are worthy of attention.

Precautions for lab mineral flotation

1. Flotation equipment and settings:

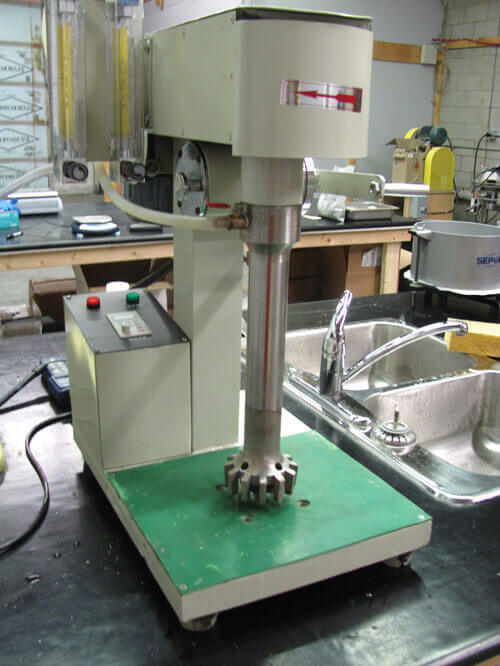

The success of a mineral flotation experiment depends largely on the quality and accuracy of the equipment and setup used. It is imperative to choose a high-quality flotation machine that can effectively separate different minerals based on their hydrophobicity. These machines should have adjustable impeller speed, aeration rate and foam depth control for optimal testing conditions. Furthermore, the availability of auxiliary equipment such as pH meters and particle size analyzers is crucial for accurate monitoring and control of experimental variables.

In order to obtain reliable data in mineral flotation experiments, it is important to carefully set the parameters of the equipment used. Proper adjustment of pulp density ensures thorough mixing and excellent particle suspension throughout the process. Adding the right reagents at the right dosage helps optimize chemical reactions within the system. Additionally, controlling factors such as water temperature and pH may significantly affect bubble formation and adhesion to mineral surfaces, thereby positively affecting flotation efficiency.

With AAF International’s state-of-the-art flotation equipment with versatile setup and complementary auxiliary tools, researchers can confidently tackle mineral separation challenges while maximizing productivity through precise experimental control.

2. Security measures

A key safety measure is wearing appropriate personal protective equipment (PPE) such as goggles, gloves, lab coats, and closed-toed shoes. These will help prevent chemical splashes, burns from hot materials, and any other physical harm.

Another important aspect of safety in mineral flotation experiments is proper ventilation of the laboratory. Flotation reagents may release harmful fumes or gases if not handled properly or in a well-ventilated space. Ensuring adequate ventilation in experimental areas can minimize exposure risks and maintain a safe working environment for researchers.

Additionally, it is crucial to maintain good housekeeping during mineral flotation experiments. Keeping your workspace clean and organized reduces tripping hazards and minimizes the risk of accidents caused by cluttered environments. Regular inspection of equipment such as flotation machines for any signs of damage or malfunction will also contribute to safer experimental practices.

4. Working environment

When conducting mineral flotation experiments, it is recommended to have a well-ventilated laboratory space. Many of the chemicals used in these experiments produce dangerous fumes or vapors that can be harmful if inhaled. Proper ventilation helps minimize exposure and ensure a safe work environment.

By following these precautions, researchers can improve the accuracy and reliability of laboratory mineral flotation experiments while ensuring the safety and integrity of their results. Asia-Africa International provides professional mineral testing services and equipment; please contact us online!