Lab mineral processing test methods include crushing, grinding, gravity separation, flotation, magnetic separation, electric separation and other processes. Among them, flotation test is a technical method used in mineral processing engineering. It simulates the industrial flotation process under laboratory conditions to study and determine the best flotation conditions and reagent formula. Laboratory flotation is often used to study the flotation effect of various minerals such as copper, nickel, lead and zinc, gold, iron, cobalt, and sulfur. This test is an important part of optimizing the recovery rate of ore dressing plants. It can help miners understand the flotation characteristics of ore and adjust and improve the flotation process according to the experimental results.

What is laboratory flotation testing?

Laboratory flotation testing is a vital technical means in the mining industry. It involves the experimental process of simulating the flotation of mineral samples in order to optimize the mineral processing technology and improve the recovery rate and quality of mineral resources. By precisely controlling laboratory conditions, including key parameters such as reagent addition, pH value, temperature, stirring speed, etc., laboratory flotation testing can provide valuable information about mineral floatability, reagent action mechanism and optimal flotation conditions. This information is crucial for designing and adjusting industrial-scale flotation processes, helping to ensure the economic efficiency and environmental compliance of the mineral processing process.

Purpose of laboratory flotation testing

Determine the floatability of the ore

Laboratory testing can be used to evaluate the flotation characteristics of different ores or mineral components, understand their reactivity to reagents, and their behavior under different flotation conditions.

Optimize reagent formulation and dosage:

Laboratory testing can help determine and optimize the optimal dosage and combination of reagents such as collectors, frothers, and regulators to achieve the best mineral processing results.

Predict flotation performance

Laboratory flotation tests can predict the performance of industrial-scale flotation operations and provide a scientific basis for the design of industrial flotation processes.

Save flotation process costs

Testing at a laboratory scale can reduce unnecessary large-scale industrial-scale tests, save time and cost, and reduce risks.

The data and results after the lab flotation experiment can help mining companies make decisions on the design, transformation and optimization of mineral processing processes. It can not only provide key data and information for industrial applications, but also provide guidance for improving mineral processing efficiency and economy.

Laboratory flotation test precautions

Laboratory flotation test is a very important part of mineral processing research. In order to ensure the accuracy and repeatability of the test results, the following are six things to pay attention to when conducting laboratory flotation tests:

1. Sample preparation and particle size analysis: Ensure that the ore sample is representative and fully mixed to reduce sampling and analysis errors. This requires that scientific methods must be strictly followed during the collection, preparation and storage of ore samples. The ore particle size has a significant impact on the flotation effect, which mainly depends on the size of the ore sample. Crushing , particle size analysis or grinding to a particle size suitable for flotation is carried out according to needs.

2. Precise reagent addition: Select appropriate collectors, frothers, depressants and other reagents, and add them strictly according to the test plan to ensure the flotation effect. In flotation tests, the type, amount and time of reagents also have a decisive influence on the experimental results. Precise measuring equipment and standardized flotation testing flow are required to add reagents to ensure the consistency of experimental conditions each time.

3. Control flotation conditions: Including temperature, pH value, reagent addition amount, stirring speed and flotation time. These conditions must remain stable and as consistent as possible with the conditions in the industrial flotation process. It is necessary to ensure that the temperature is controlled within the range of the experimental design; pH meter or buffer solution can be used to accurately control the pH of the slurry. The control of stirring speed and flotation time in the laboratory flotation machine is mainly conducive to the dispersion and mixing of minerals. We will select appropriate parameters and keep them consistent according to the characteristics of the minerals and the purpose of the experiment to ensure that the flotation machine has the best reaction rate and effect.

4. Systematic testing process: The testing process should be flexible so that different variables can be controlled and optimized. Before the test begins, it is necessary to clarify every stage of the flotation experiment, including ore sample processing, flotation machine preparation, reagent preparation and addition sequence, and detailed experimental condition setting. Design a reasonable mineral testing process to systematically determine the optimal flotation conditions.

5. Data recording and analysis: During the experiment, detailed data such as the raw materials used in each experiment, the ratio of reagents, the order of addition, and the specific conditions of the flotation operation should be recorded in detail to facilitate subsequent analysis and optimization. This helps to identify key variables and possible sources of error in the experiment.

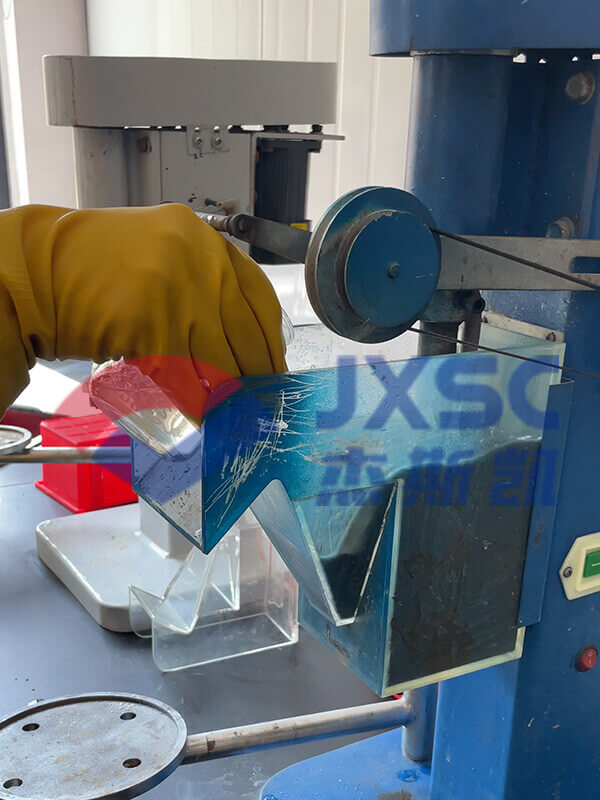

6. Safety and environmental protection: In flotation experiments, protective equipment such as gloves are used. In addition, various chemical reagents that may be used during the experiment and the tailings and waste generated need to be handled promptly and properly to reduce the impact on the environment.

Laboratory flotation testing provides a theoretical and practical basis for actual production, and is an important means to improve mineral processing efficiency, ensure effective resource utilization, and reduce production costs. By precisely controlling experimental conditions and systematically analyzing data, laboratory flotation testing can not only predict the effect of industrial flotation, but also reveal problems that may be encountered during ore processing, and provide precise adjustment basis for solving these problems. Asia-Africa International (JXSC) supports customized mineral processing testing services and equipment, contact us for details and the latest quotation!