Spodumene is a “fascinating” mineral that has always attracted attention from the industrial and technological fields. This lithium-rich silicate mineral is widely sought after for its high lithium content, making it a key ingredient in the production of rechargeable batteries for electric vehicles and portable electronic devices. Its unique crystal structure also gives it potential as a gemstone, often referred to as a hidden stone or kunzite, and its vibrant green and pink hues attract collectors and jewelry enthusiasts.

Spodumene has multifunctional properties, and ongoing research aims to improve beneficiation techniques and utilize its properties more effectively. In addition, beneficiation testing helps to understand the characteristics of spodumene ore, allowing the development of specialized processing techniques that ultimately improve product quality and reduce impurities. As demand for lithium-ion batteries increases, especially in the transition to sustainable energy, rigorous spodumene beneficiation testing has become more critical than ever. Mining companies can optimize their processes to recover high-grade lithium concentrates efficiently by comprehensively testing spodumene ores.

Laboratory spodumene beneficiation test methods

Laboratory beneficiation testing methods for spodumene involve complex processes to maximize lithium recovery while minimizing impurities. Gravity, flotation, magnetic separation, and other technologies are used to obtain high-purity concentrates.

1. Spodumene beneficiation test-gravity separation

Extracting lithium from spodumene ore offers a promising approach. Gravity separation can effectively separate spodumene from other gangue minerals using mineral density differences, resulting in higher concentrate grades. Compared with other mineral processing technologies, this method not only minimizes the use of reagents, but also reduces energy consumption. Furthermore, gravity separation has shown the potential to achieve high recovery rates while maintaining product quality, making it an attractive option for spodumene processing.

The successful application of gravity separation in spodumene beneficiation trials has provided valuable insights into optimizing process parameters. Fine-tuning variables such as feed particle size, water flow rate, and deck slope can greatly affect separation efficiency and concentrate production. As technology advances, innovative equipment design and process optimization can further improve the effectiveness of gravity separation in spodumene beneficiation. Ultimately, this approach holds great promise for sustainable lithium production by providing a cost-effective and environmentally friendly solution for spodumene ore processing.

2. Spodumene beneficiation test – flotation

Flotation separation has become essential in spodumene beneficiation testing, providing promising results for improving lithium recovery. Flotation technology can be used to extract spodumene from complex ore bodies efficiently, helping to enhance purity and economic viability. By implementing innovative reagent protocols and advanced equipment, flotation separations demonstrate the potential to optimize spodumene concentration through a robust and cost-effective method. Ongoing research and development in this area drive the field toward greater spodumene beneficiation efficiencies.

The continuous development of spodumene beneficiation and flotation technology proves the dynamic characteristics of beneficiation technology. Focused on maximizing lithium production while minimizing environmental impact, researchers are exploring new ways to improve the efficiency and sustainability of flotation separation methods. Additionally, integrating data analytics and machine learning algorithms is expected to revolutionize spodumene beneficiation testing by enabling real-time monitoring and adaptive control systems. This renewed emphasis on innovation underscores the industry’s commitment to meeting current needs and paving the way for future advances in spodumene processing technology.

3. Spodumene beneficiation test – magnetic separation

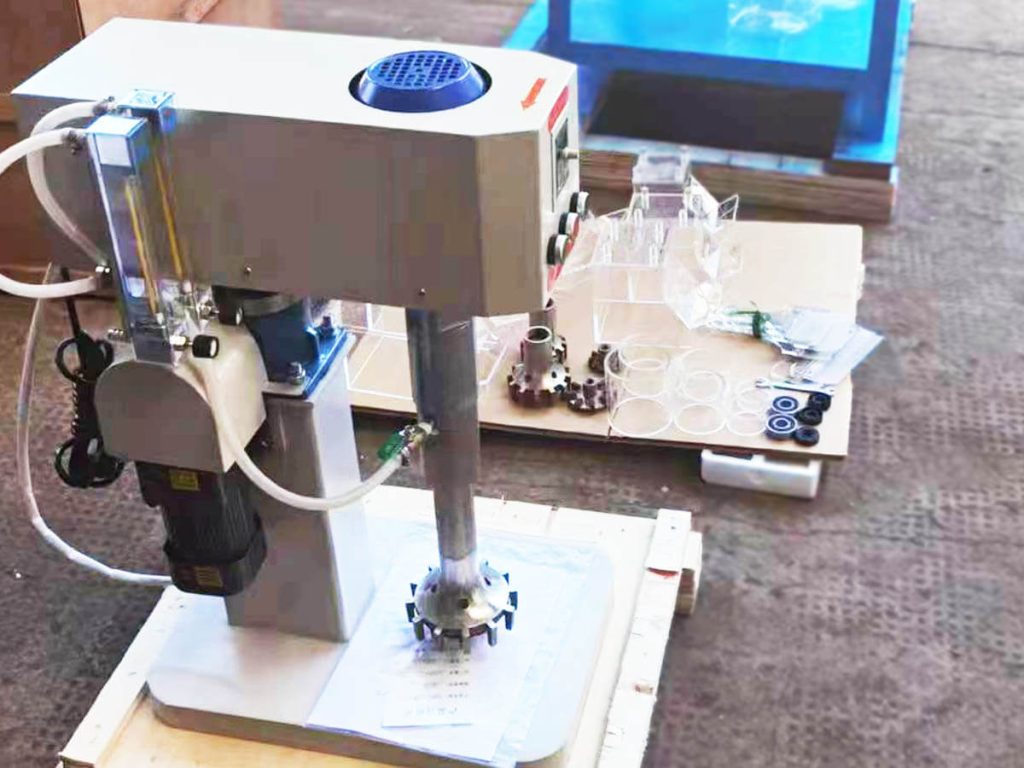

In spodumene beneficiation testing, high-intensity magnetic separators can effectively extract spodumene by exploiting its paramagnetic properties, thus promising to improve spodumene concentrates’ overall recovery and purity. This technology solves problems related to mineral processing efficiency, but also helps reduce environmental impact by minimizing tailings and improving resource utilization.

In addition, recent advances in magnetic separation technology have led to a better understanding of process parameters and their impact on spodumene beneficiation test results. From optimizing magnetic field strength to fine-tuning particle size distribution, researchers are delving into the nuances of this approach to unlock its full potential. As a result, the industry has witnessed increased precision and control of the magnetic separation process, ultimately paving the way for superior product quality and operational cost savings.

Factors affecting the spodumene beneficiation process

(1) Mineralogical complexity of spodumene ore, which varies greatly

The presence of impurities such as iron, mica, and other minerals can significantly affect the beneficiation process, so a thorough analysis is crucial before testing begins. In addition, the particle size distribution of spodumene ore also plays a crucial role in determining the effectiveness of mineral processing tests. Fine particles may require different handling techniques compared to coarser particles, resulting in different results during testing.

(2)Chemical composition of spodumene ore

Changes in lithium content and the composition of other elements within the deposit can significantly affect flotation and other separation processes. Understanding these changes is critical to obtaining accurate and reliable test results. External factors such as temperature, pH, and water quality during laboratory testing can also affect spodumene beneficiation results.

Considering these various factors is the basis for successful spodumene beneficiation testing, and we should use high-quality equipment and beneficiation technology to maximize valuable minerals.

Spodumene beneficiation testing is essential in extracting lithium, a key element in making batteries and other electronic devices. By conducting thorough beneficiation testing, companies can determine the most effective way to separate spodumene from other minerals present in the ore, thereby increasing yields and reducing production costs. Understanding particle size, chemical composition, and mineral combinations can lead to innovative solutions and increased efficiency. Asia-Africa International provides accurate and high-quality mineral processing testing services and equipment, which can comprehensively test and better understand the composition and characteristics of the ore, and then select the best mineral processing method to extract the concentrate.