Usually, the industrial shaking table refers to the mineral processing shaker table. It is mainly composed of a frame, a bed surface and a transmission mechanism. It cooperates with the flushing tank, feeding trough and machine base to form a complete sorting process. The shaking table mainly makes the materials move in different directions along the bed surface according to the density and particle size of the materials, so as to achieve the purpose of accurately separating materials of different qualities. In mineral processing, the shaking table can not only be used as an independent method, but also often combined with magnetic separation, flotation, jig, centrifuge, spiral chute, etc. However, the laboratory shaker table size is smaller than that of ordinary production shakers, so it is suitable for carrying out ore selectivity research, small processing capacity, and small-scale mineral processing plants. It can produce high-grade concentrate, sub-concentrate, medium ore and tailings products at one time. It can quickly obtain test results and know whether the gravity separation process maximizes recovery rate and is suitable for production. Next, we will introduce two types of shaker tables commonly used in laboratory mineral processing.

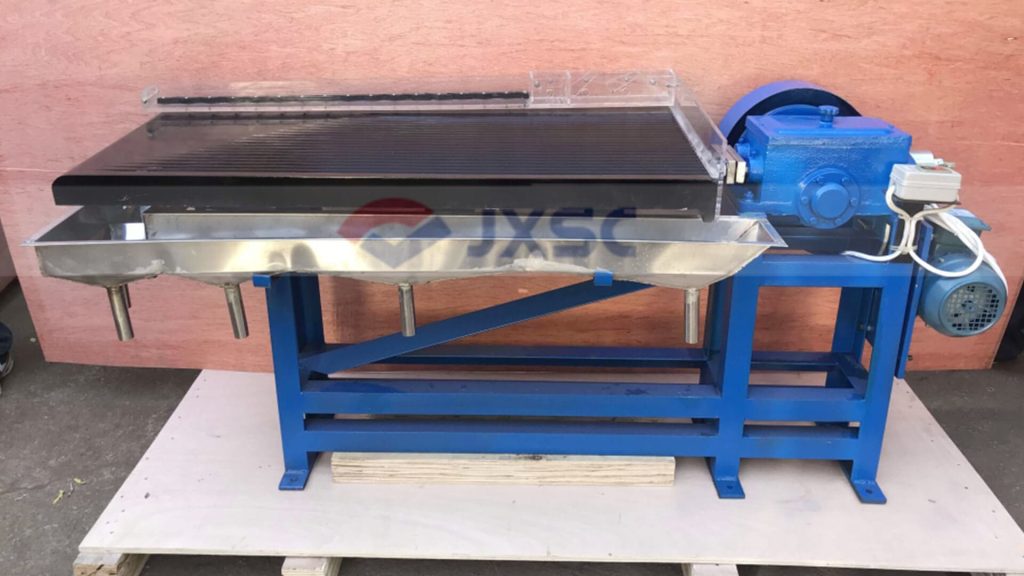

1. LY Shaking Table

This lab shaking table is an efficient gravity separation equipment for selecting fine-grained ores. Suitable for sorting iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphoethite, tungsten ore, tin ore, tantalum ore, and niobium with fine materials with a particle size of 0.074-2 mm. Minerals and rare metals, metallic ores, and non-metallic minerals with different specific gravity. The bed surface of this laboratory shaker is divided into three specifications: coarse, medium and fine. Please contact us for details. It mainly uses the combined action of mechanical asymmetric reciprocating motion and thin-layer inclined plane water flow on an inclined bed surface to make the mineral particles loose, layered and zoned in a fan shape on the bed surface, so that the minerals are processed according to different densities. The sorting process. The shaker has a wide, approximately rectangular bed surface and can handle several products of different qualities at one time. Minerals with different specific gravity are clearly zoned on the bed surface, and the sorting effect is good. Its precise control capabilities combined with its compact design make it an essential instrument for conducting mineral gravity separation process research.

Working Principle

The ore particles are fed from the ore feeding trough at the corner of the bed surface, and the horizontal flushing water is supplied from the feeding trough. The bed strips or grooves on the bed surface are longitudinal and nearly perpendicular to the direction of the water flow. When the water flows transversely, a vortex is formed in the groove. The combined action of eddy currents and bed shaking causes the mineral sand layers to become loose and stratified according to density, with heavy minerals moving to the lower layer and light minerals moving to the upper layer. The light mineral particles in the upper layer are subject to greater impact, and most of them move downward along the bed surface and become tailings. The heavy mineral particles located at the bottom of the bed move longitudinally due to the differential motion of the bed surface, and are discharged from the opposite side of the transmission end to become concentrate. However, medium-density particles lie somewhere in between. It can finally be divided into concentrate, medium ore and tailings.

Features Of LY Shaking Tables

- The sorting process is stable and easy to control, and the ore concentration is allowed to vary within a wide range

- It has a high rich ore ratio and is commonly used to obtain final concentrates and tailings, and can effectively handle fine-grained materials.

- Easy to install, small footprint, low energy consumption and low cost.

2. Gemini shaker table

Gemini shaker table is an equipment that realizes gravity separation of minerals mainly by utilizing the differences in relative density, particle size and shape between the mineral particles to be sorted, as well as the different speed and direction in the aqueous medium. Ideal for processing material sizes between 30 microns and 2 mm, such as precious metals such as gold and palladium. The unique “pentagonal” bed design is often used to recover gold minerals into concentrates that can be directly smelted. In a controlled laboratory environment, the Gemini shaker tale accurately separates valuable minerals from gangue material, providing optimal results for testing the effectiveness of the gravity separation process.

Features Of Gemini Shaking Table

- It has low energy consumption and can maximize the enrichment rate of ore.

- Adjustable tilt angle and water flow further improve the efficiency of separating different types of minerals.

- Its compact design allows it to fit easily into laboratory spaces while still providing a large work surface for sample processing.

LY shaking tables and Gemini shaker tables provide reliable equipment for the precise and accurate study of mineral enrichment processes, and play an important role in advancing laboratory mineral processing research and development work. Both shaker tables feature adjustable settings, allowing researchers to optimize laboratory beneficiation processes based on the specific characteristics of the ore being tested, resulting in more accurate results and improved recoveries. In order to obtain the best test results, Asia-Africa International supports customized laboratory equipment and testing services. Contact us for more details!