Analytical & Mineralogy

We (Asia-Africa International) supply comprehensive mineral identification, including physical and chemical properties analysis, crystallography, and spectroscopy, enabling clients to determine the exact mineral species present in their samples. We are staffed by a team of experienced mineralogists and analytical scientists who possess in-depth knowledge of mineralogy and related disciplines to provide valuable insights into the mineralogical composition and texture of ore samples, which helps clients optimize their mineral processing operations, improve extraction efficiency, and maximize resource recovery. We couple with advanced analytical instrumentation to provide empirical data to inform your every decision. And we offer tailored analytical solutions to meet the specific needs of clients.

Lab Analytical & Mineralogy Testing

Introduction

Analytical and mineralogy refers to the scientific study and analysis of minerals in a laboratory setting. It involves applying various techniques and methodologies to examine minerals’ physical, chemical, and crystallographic properties. The goal is to identify and characterize mineral species in geological samples, ores, environmental matrices, or archaeological artifacts.

Spectral analysis and chemical analysis can only find out the types and contents of elements contained in the ore. In contrast, mineral analysis can further find out what kind of minerals the various elements in the ore exist, the content of multiple minerals, embedded particle size characteristics, and the symbiotic interaction relationship between them. The research methods are usually phase analysis and rock ore identification. Through mineral analysis, we can clarify minerals’ origin and enrichment rules under different geological processes.

Lab mineral analytical and mineralogy can use to identify mineral species and understand their characteristics and properties. At Asia-Africa International, we offer a wide range of mineral analytical testing.

Mineral Analysis Methods

- Mechanical separation methods: sorting, washing, heavy liquid separation, magnetic gravity separation, electrochemical separation, etc.,

- Physical methods: binocular stereo microscope identification, polarizing microscope identification, X-ray differential thermal analysis, electron microscope identification, electron probe, etc.,

- Chemical methods: blowpipe analysis, microchemical analysis, complete chemical analysis, spectral analysis, polarographic analysis, etc.

Work Principle

Phase analysis is a method that uses the different solubility and dissolution rates of various minerals in various solvents in the ore to separate multiple minerals and measure the existence & content of a particular element in the sample. Phase analysis can perform on the following elements: copper, lead, zinc, manganese, iron, tungsten, tin, antimony, cobalt, nickel, titanium, aluminum, arsenic, mercury, silicon, sulfur, phosphorus, molybdenum, germanium, indium, Beryllium, Uranium, Cadmium, etc.

By identifying rocks and minerals, we can know what minerals beneficial and harmful elements exist in; find out the type, content, distribution, particle size characteristics, and mosaic relationship of minerals in ore; measure the dissociation degree of functional mineral monomers in mineral processing products. Standard methods of determination include the naked eye and microscope identification. Commonly used microscopes include solid microscopes (binocular microscopes), polarizing microscopes, and reflective microscopes.

Main Testing Steps

Step 1: Sample Collection & Preparation

- Obtain representative mineral samples from geological formations, ores, or other sources.

- Clean and remove impurities or foreign substances from the samples.

- Crush, grind, and sieve the samples to obtain homogenous and fine-grained specimens suitable for analysis.

Step 2: Instrumentation and Technique Selection

Different analytical techniques and instruments are utilized based on the specific objectives of the analysis. The choice of technique depends on the properties of the minerals being studied, the desired level of detail, and the available equipment. Common techniques employed in analytical and mineralogy work include optical microscopy, X-ray diffraction (XRD), scanning electron microscopy (SEM), electron microprobe analysis (EMPA), spectroscopy (such as infrared or Raman spectroscopy), and various chemical analysis methods.

Step 3: Mineral Identification and Characterization

The primary objective of analytical and mineralogy work is to identify and characterize minerals accurately. This involves examining the physical, chemical, and crystallographic properties of the minerals. Optical microscopy provides information on mineral color, texture, and other visual properties. XRD is used to determine the crystal structure and mineral composition. SEM and EMPA allow for high-resolution imaging and elemental analysis. Spectroscopy provides insights into chemical bonds and molecular structure. Chemical analysis techniques such as XRF, ICP-MS, or AAS are employed to quantify elemental concentrations.

Optical Microscopy

Optical microscopy is a fundamental method in mineral analysis research. Examine the mineral samples under a polarizing microscope. Observe the mineral’s physical properties, crystal morphology, textures, and mineral associations. And Identify minerals based on their optical properties, such as color, transparency, and birefringence. This method provides valuable information about mineral identification, crystal structure, and textures.

X-ray Diffraction (XRD)

XRD is a widely used method in mineral analysis research to determine the crystal structure and mineral composition. It involves passing X-rays through a mineral sample and analyzing its diffraction pattern. Compare the diffraction pattern with a database of known mineral patterns to identify the minerals and provide information about their crystallographic properties, including lattice parameters, unit cell dimensions, and crystal habit.

Electron Microscopy(SEM, ESD, TEM)

- Scanning electron microscopy (SEM): Examine the mineral surfaces at high resolution.

- Energy-dispersive X-ray spectroscopy (EDS): Obtain images of mineral morphology, textures, and elemental composition using.

- Transmission electron microscopy (TEM): Detailed analysis of mineral structures at the atomic scale.

Spectroscopy

We employ spectroscopic techniques, such as infrared spectroscopy (IR) or Raman spectroscopy, to study the molecular structure and chemical bonds in minerals. And collect spectral data and compare it with reference spectra to identify mineral species and functional groups.

Chemical Analysis

Chemical analysis methods, including X-ray fluorescence (XRF), inductively coupled plasma optical emission spectroscopy (ICP-OES), and atomic absorption spectroscopy (AAS), are employed to determine the chemical composition of minerals. The chemical analysis quantifies various elements’ concentrations and can provide insights into the mineral’s geochemical characteristics.

Step 4: Data Interpretation and Analysis

The collected data from various mineral analysis techniques are analyzed and interpreted to understand the mineral’s characteristics, relationships, and geological significance. Statistical analysis, data visualization, and geological modeling may be employed to derive meaningful conclusions from the data.The interpretation of the data may require expertise and knowledge in mineralogy, geology, and related fields.

Step 5: Reporting and Documentation

Prepare comprehensive reports summarizing the analysis and findings.

These reports include detailed information about the samples, analysis techniques used, identified minerals, their compositions, crystallographic properties, and any interpretations or conclusions drawn from the data. The reports serve as valuable references for research, mining exploration, environmental assessments, and other applications.

Throughout the analytical process, quality control measures are implemented to ensure accuracy and reliability of the results.

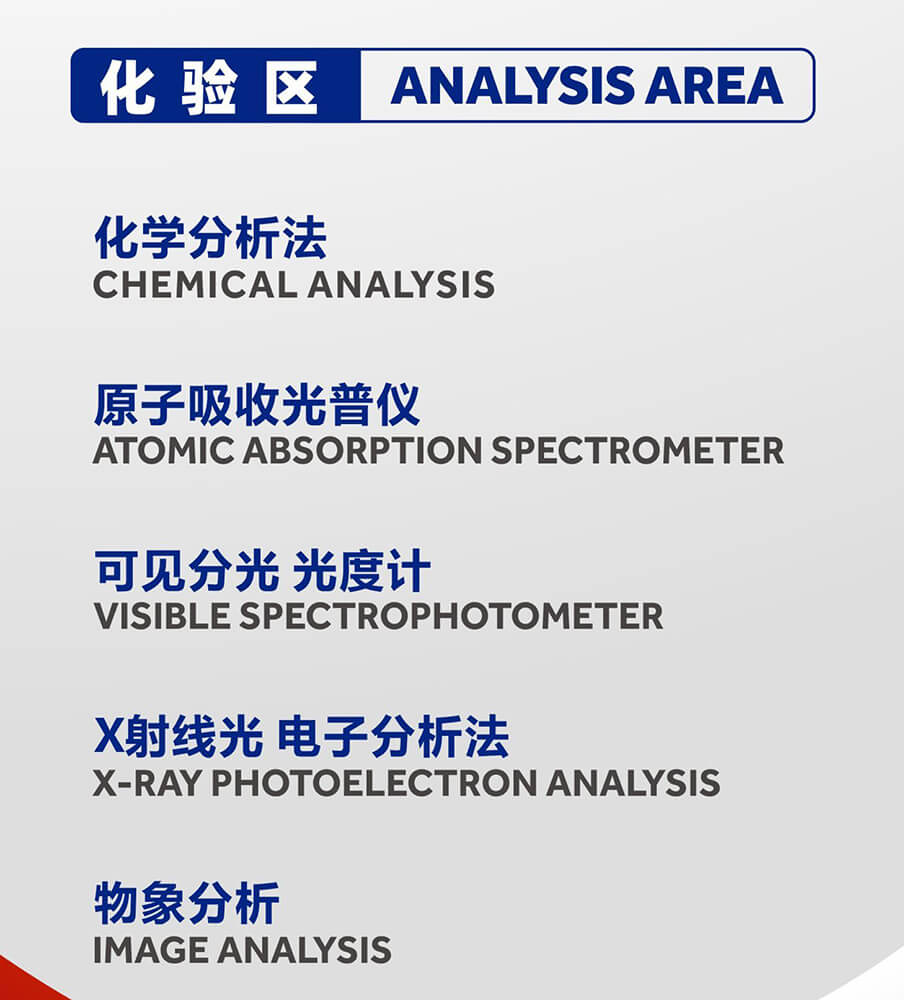

Equipment For Analytical & Mineralogy

Commonly used equipment in lab mineral analytical & mineralogy testing

- Crushing equipment

- Grinding equipment

- Screening equipment

- Optical microscope

- X-ray photoelectron analyzer

- Scanning electron microscope

- Electron Microprobe Analyzer

- Spectrometer

- Spectrophotometer